Insights > Article > Posted: 2023-Nov-16, Updated: 2025-Dec-23

Window Weatherstripping: When to Repair vs. When to Replace

While adding supplemental weatherstripping can offer an immediate boost in comfort, it raises a critical question: Can a DIY solution ever match the permanent, precision-engineered seal of a brand new window replacement?

This article explores the balance between temporary home maintenance and long-term energy efficiency. It provides a comprehensive guide to the various types of DIY weatherstripping, such as foam tape, V-strips, and pile, detailing how they function as immediate "stop-gap" solutions for drafts and noise.

In this article:

- Pre-installed weatherstripping solutions

- Retrofit weatherstripping solutions

- The limits of DIY: When weatherstripping isn’t enough

- Still feels cold after sealing the gap

- Why factory weatherstripping is built to last (and hard to replace)

- Bulb weatherstripping

- Compression weatherstripping

- Pile weatherstripping

- V-strip weatherstripping

- Adhesive-backed foam tape weatherstripping

- Brush-type weatherstripping

- Interlocking metal weatherstripping

- Fin seal weatherstripping

- Summary

- Related Articles

- Request a quote

Each weatherstripping option holds a trove of unique advantages and considerations, carefully curated to meet your home's demands. It's a quest for the perfect match, bidding farewell to pesky drafts and ushering in the era of weather protection. Most manufacturers will often use more than one type of weatherstripping on a single window or door for maximum protection from the elements.

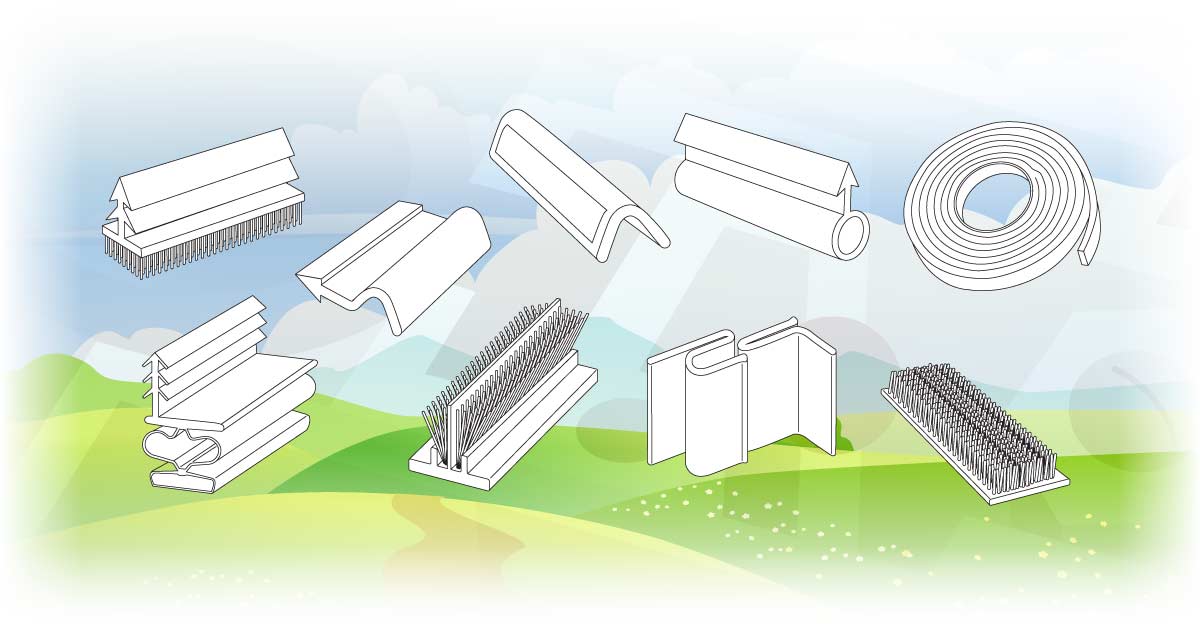

There are plenty of types and formats of weatherstripping. This article covers some of the more common types:

Pre-installed weatherstripping

Pre-installed weatherstripping is seamlessly incorporated into the manufacturing process to ensure effective sealing and insulation right from the start of the window or door's life cycle.

Retrofit weatherstripping

Retrofit weatherstripping can be added to older structures to seal gaps and reduce air leakage. Availability and suitability of these options may vary based on window type, size, and personal preferences. Consult professionals or follow manufacturer recommendations for the best retrofit weatherstripping for your windows.

*While we don’t provide stand-alone retrofit repair services, these industrial-grade weatherstripping technologies are used in a variety of the new window brands we install to ensure lifetime performance.

The limits of DIY

While weatherstripping is an excellent maintenance step, it cannot fix a window that has reached the end of its lifespan. If your window frames are warped, the wood is beginning to rot, or you notice "fogging" between the panes (a sign of a blown seal), new foam or V-strips won’t solve the underlying issue. In these cases, air isn't just leaking around the sash; it's often moving through the structural gaps of the window itself. If you find yourself replacing your weatherstripping every year and the drafts persist, it’s a clear signal that the window’s structural integrity has failed, and a permanent replacement is the only way to restore your home’s comfort.

Still feels cold after sealing the gap

Many homeowners are surprised to find that even after perfectly sealing every crack, their room still feels chilly. This is often due to "radiant heat loss." Older glass technology lacks the Low-E coatings and Argon gas fills found in modern high-performance windows. Even if no air is physically blowing through, an old pane of glass becomes a "cold radiator," sucking the heat out of your body and your furniture. By upgrading to energy-efficient replacement windows, you aren’t just stopping the wind; you’re creating a thermal barrier that keeps the heat exactly where it belongs, inside your home.

Why factory weatherstripping is built to last (and hard to replace)

Unlike peel-and-stick retail options, manufacturer-grade weatherstripping is integrated during the assembly process using specialised industrial equipment. These seals are often heat-welded or mechanically inserted into precision-routed grooves (kerfs) that require robotic accuracy to ensure a perfect, airtight fit.

Because they are installed under calibrated tension while the window is being built, they are nearly impossible to replicate or "re-thread" by hand once the window is in your wall. Attempting a manual replacement often leads to stretched material and uneven gaps, which is why a DIY retrofit can rarely match the performance of a factory-certified original.

Bulb weatherstripping

Bulb seal weatherstripping consists of a flexible bulb-shaped section made of rubber or silicone, attached to a base that is mounted on/in the sash or frame. The bulb compresses when the window is closed, forming a seal against drafts and moisture.

Pros:

- Creates a tight and effective seal against drafts and moisture

- Durable and long-lasting

- Can accommodate different sash or frame sizes

- Relatively easy to install

Cons:

- Installation may require more effort and precision

- May affect the smooth operation of sliding windows if not properly installed

Compression weatherstripping

Made of rubber or silicone, compression seals are an effective solution for sealing residential windows. They create a superior tight seal when the window is closed, reducing air infiltration and improving energy efficiency

Pros:

- Excellent sealing properties, reducing drafts and air infiltration

- Durable and long-lasting

- Provides good resistance to moisture, UV rays, and temperature changes

- Sometimes available in various colours and styles to match different window frames

Cons:

- May be more expensive compared to other weatherstripping options

- Some compression seals may cause friction and affect the smooth operation of sliding windows

- Compression seals with harder densities may require more force to close the window

Pile weatherstripping

Consists of a strip made of thin fibres, typically nylon or polyester, that are attached to a flexible backing material. The fibres are densely packed together, creating a fuzzy or brush-like surface.

Pros:

- Pile weatherstripping forms a tight seal when compressed, effectively blocking drafts and reducing air leakage

- It can be used in various types of openings, such as sliding windows, casement windows, and sliding doors

- Can accommodate different sash or frame sizes

- Durable and resistant to wear and tear

- Relatively easy to install

Cons:

- Limited effectiveness for large gaps

- May affect the smooth operation of sliding windows if not properly installed

- Can absorb moisture, which may lead to mould or mildew growth over time if not properly maintained

- If damaged or worn out, it may require a complete replacement

- May have a higher upfront cost compared to other types of weatherstripping materials

- May not be as effective as other specialised soundproofing materials

V-strip weatherstripping

V-strip weatherstripping is commonly used in residential windows. It is made of durable vinyl or metal and is inserted into a groove or mounted on the sash or frame. V-strip creates a tight seal between the sash and frame, reducing air and water infiltration.

Pros:

- Effective in sealing air and water leaks

- Durable and long-lasting

- Can accommodate wider gaps and irregular surfaces

- Relatively easy to install and replace

Cons:

- Usually available only in black or white

- The metal variant may corrode over time if not properly maintained

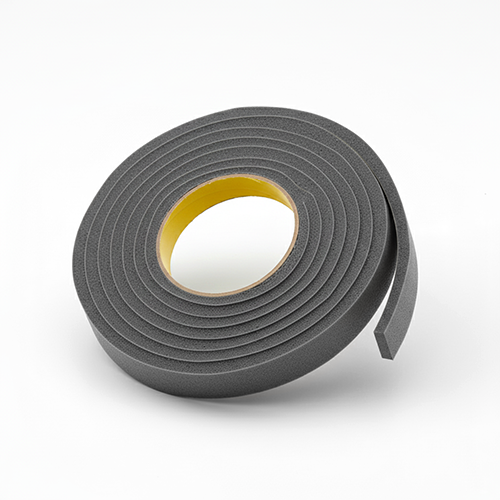

Adhesive-backed foam tape weatherstripping

Adhesive-backed foam strip weatherstripping usually consists of a broader strip or roll of foam material with adhesive backing along one side or both sides. This type of weatherstripping is designed specifically for larger gaps or wider surfaces, such as window frames. The adhesive-backed foam strip weatherstripping provides a wider coverage area for improved sealing and insulation.

Pros:

- Easy and quick installation

- Cost-effective and readily available

- Provides good insulation for smaller gaps

- Can be trimmed to fit different window sizes

Cons:

- Not as durable as other weatherstripping materials

- May lose adhesion over time, especially in high-temperature environments

- Susceptible to damage from moisture or UV exposure

- May not be suitable for wider gaps or high-traffic areas

Brush-type weatherstripping

Brush-type weatherstripping, also known as bristle or brush weatherstripping, is a type of weatherproofing material used to seal gaps and provide insulation around windows and doors

Pros:

- Blocks drafts and prevents air infiltration at the bottom of the door

- Adds a barrier against dust, insects, and noise

- Improves energy efficiency by reducing heat loss and maintaining indoor temperature

- Durable and long-lasting, designed for regular use and foot traffic

- Easy to install, usually attached to the bottom of the door with screws or adhesive

- Available in various materials, styles, and sizes to match different door types and preferences

Cons:

- May need periodic adjustment or replacement due to wear and tear

- Installation may require modification or trimming of the door in some cases

- Limited effectiveness in sealing uneven or irregular surfaces

- Not suitable for doors with excessive clearance or uneven flooring

- May cause slight resistance when opening or closing the door

- Regular cleaning is necessary to prevent dirt or debris buildup

Interlocking metal weatherstripping

Designed to provide a durable and effective barrier against air, water, and noise infiltration. It consists of metal strips with interlocking profiles that fit together when the door or window is closed, creating a nice, tight seal.

Pros:

- Offers excellent durability and weather resistance

- Provides a tight and secure seal against air and water infiltration

- Can accommodate wider gaps and irregular surfaces

- Long-lasting and low-maintenance

- Can provide an added layer of security by making it more difficult for intruders to manipulate or force open windows and doors.

Cons:

- Generally more expensive than other weatherstripping options

- Installation may require more effort and precision

- Regular maintenance is recommended to keep the metal weatherstripping in good condition

Fin seal weatherstripping

Fin seal weatherstripping for windows is a type of weatherstripping that utilises flexible bristles or fins attached to the window frame or sash. It creates a barrier against drafts, dust, insects, and noise while allowing for smooth window operation.

Pros:

- Blocks drafts, dust, insects, and noise effectively

- Provides a flexible seal for irregular surfaces

- Allows for easy window operation

- Durable and long-lasting

- Compatible with various window types

- Relatively easy to install and replace

Cons:

- Requires periodic cleaning to prevent dirt or debris buildup in the bristles

- Less effective in extreme weather conditions compared to other types

- May need occasional adjustment if the bristles become misaligned

- Effectiveness can vary depending on the quality and design of the weatherstripping

Summary

Understanding the Long-Term ROI It is tempting to choose a $20 roll of weatherstripping over a full window replacement, but it’s important to look at the "hidden costs" of old windows. A temporary fix might stop a whistle in the wind, but it won't address the 25–40% of energy loss occurring through outdated frames and glass.

Over five to ten years, the money "saved" by avoiding a replacement is often completely eaten up by inflated Ottawa heating and cooling bills. When you factor in the added home resale value, improved curb appeal, and the elimination of maintenance chores, a professional replacement from Bayview Windows often pays for itself far faster than a decade of DIY patches.

Related articles

Stop guessing and start saving: Get a professional assessment

If you’re tired of feeling a chill every time you walk past your windows, it’s time to move beyond the hardware store aisles. At Bayview Windows, we help Ottawa homeowners determine if their windows are candidates for a simple tune-up or if it’s time for an upgrade.

Our experts provide a transparent assessment of your home's "envelope" to ensure you aren't throwing money out the window. Don't spend another winter shivering behind plastic film and foam tape, reach out to our team today for a professional consultation and see the difference a high-quality installation can make.