Insights > Article > Posted: 2025-Nov-11, Updated: 2025-Nov-14

Laminated vs. Tempered Glass: Key Differences, Costs, and Applications in Ottawa

In this article:

Understanding the differences between these types helps you make the best decision for safety, security, energy efficiency, and long-term durability.

What Is Safety Glass?

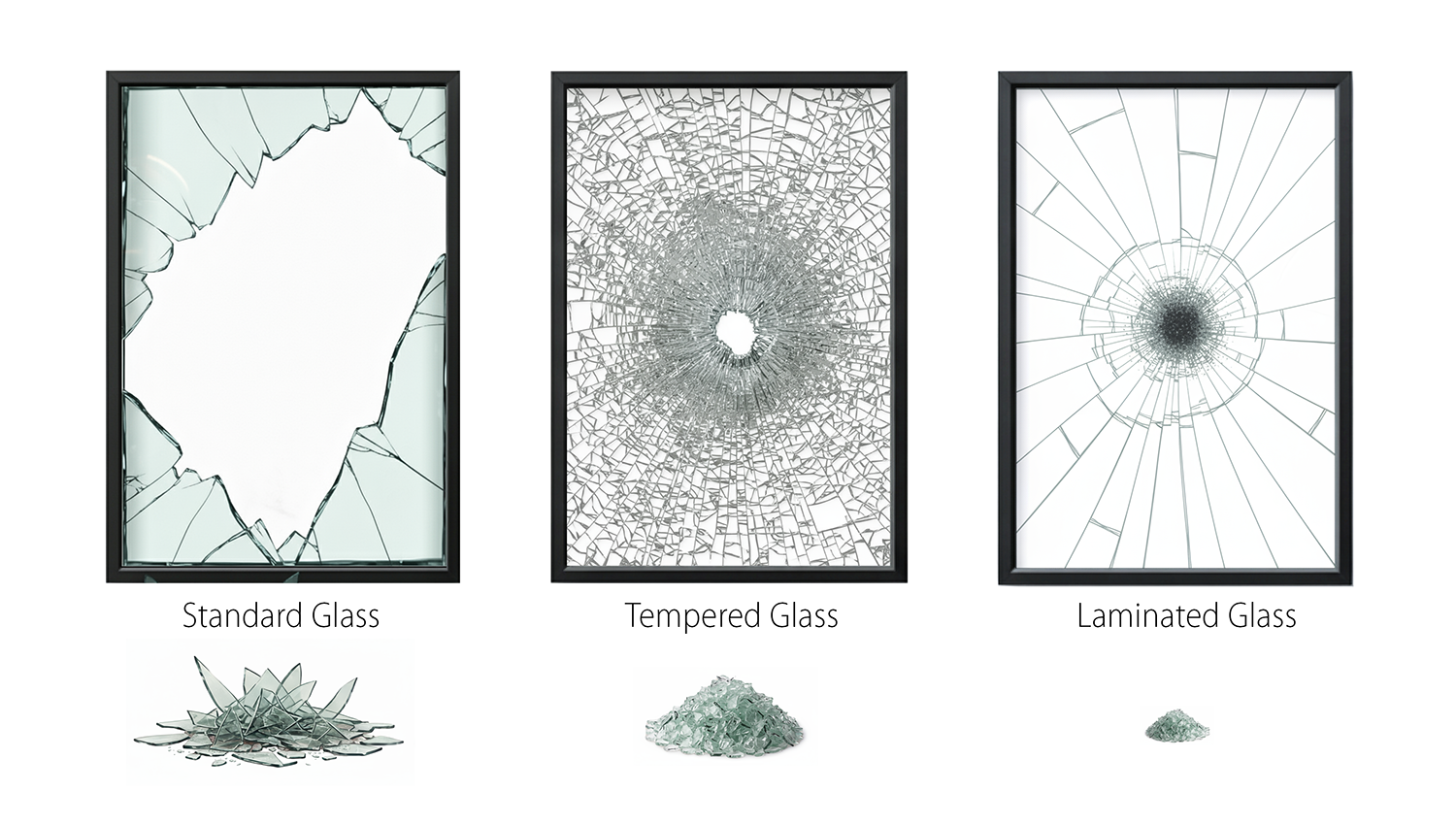

Safety glass is engineered to minimise injuries if broken. Unlike standard glass, safety glass is designed to either:

- Shatter into small, blunt fragments (tempered glass)

- Hold together via an interlayer (laminated glass)

Safety glass is commonly used in entrance doors, patio doors, large windows, skylights, and balustrades.

Tempered Glass: Affordable Strength

Tempered glass, or "toughened glass," is made by heating standard (annealed) glass to over 620∘C and then rapidly cooling it in a process called "quenching." This rapid cooling causes the outer surfaces to cool and contract quickly, putting the exterior of the glass into a state of compression and the interior into a state of tension.

Result: This built-in stress makes the glass about four to five times stronger than regular glass against surface impact and thermal stress (like a cold winter air hitting a hot interior pane).

Tempered Glass Pros

- Lower Cost: It's generally the most budget-friendly safety glass option. While it costs more than regular glass, it's typically less expensive than laminated glass for the same thickness.

- Scratch Resistance: The tempering process makes the glass's surface harder, giving it improved resistance to scratches and general wear and tear compared to regular glass.

- High Strength & Durability: Its resistance to thermal stress is a major factor, making it ideal for sunny windows, skylights, and glass near heat sources or in environments with widely fluctuating temperatures.

- Meets Building Codes: In many jurisdictions, building codes mandate the use of tempered glass in "hazardous locations" like glass doors, shower enclosures, windows close to the floor, and near pools/hot tubs, essentially making it the only compliant choice for those applications.

- Resistant to thermal stress, wind, and impact.

- If it breaks, the opening is immediately gone, but the pieces are relatively harmless.

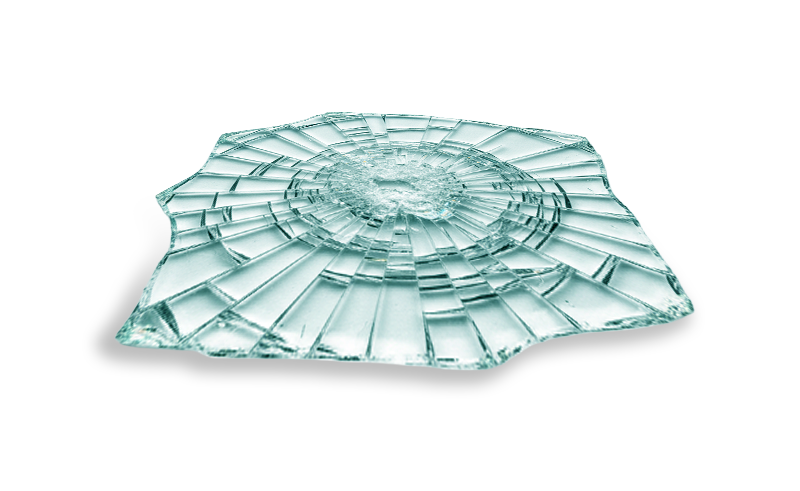

- The breakage pattern is its defining safety feature. When compromised, the stored energy releases, causing the entire pane to fracture into those small, dull fragments, significantly reducing the risk of severe lacerations.

Tempered Glass Cons

- Once the glass has gone through the tempering process, you cannot cut it, drill it, or even sand the edges. Any attempt to modify it will disrupt the internal stresses and cause the entire pane to shatter instantly. Everything, including notches and holes, must be done before tempering.

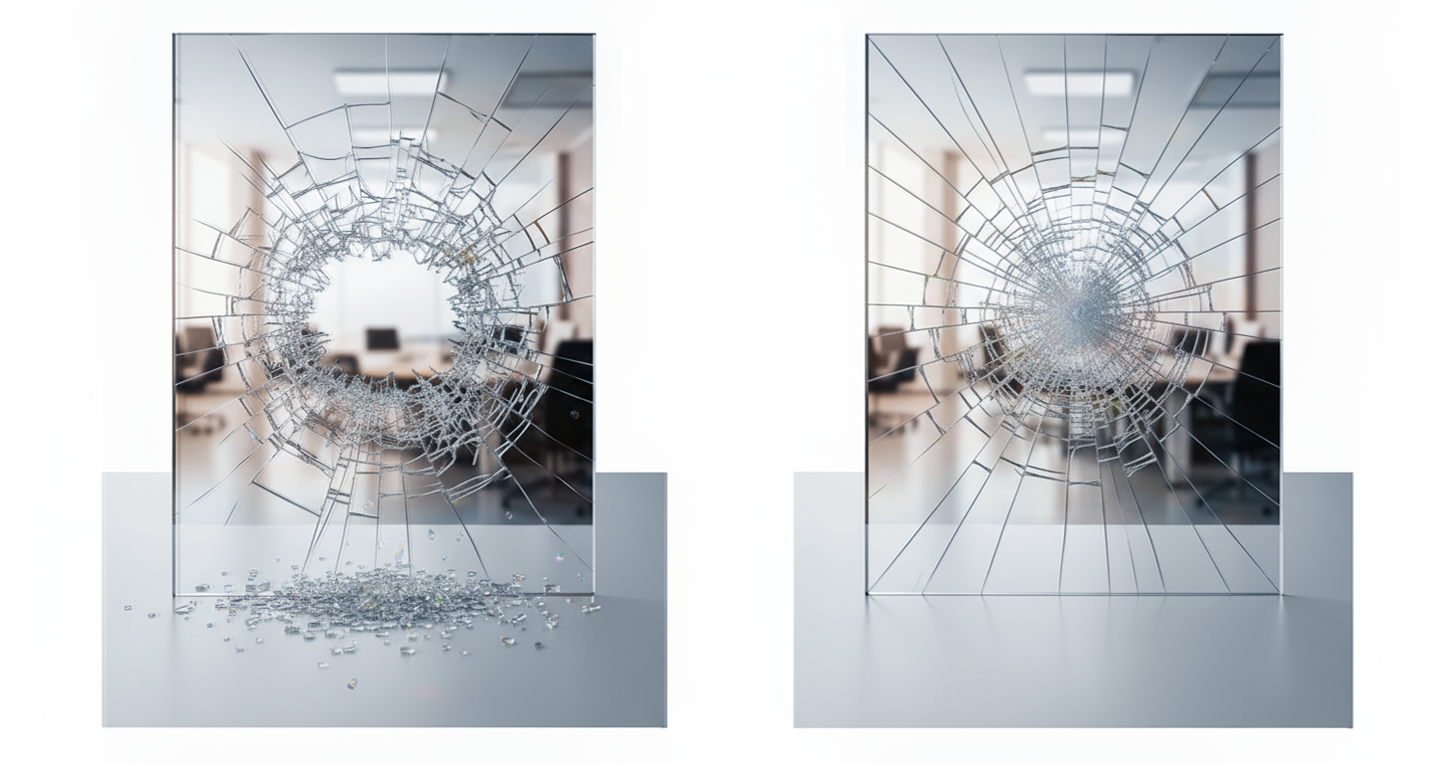

- Less Effective Against Forced Entry: This is a common misconception. While it's stronger than regular glass, if a thief hits it hard enough (say, with a rock or hammer), it will shatter completely, leaving a massive, easy-to-climb-through hole in a single blow. This provides no barrier and zero delay.

- Those "harmless" fragments still end up everywhere on the floor, requiring a complete cleanup and leaving the opening fully exposed to the elements.

Tempered glass is used for safety and durability, not just as a preference, because it is legally required by building codes for all high-risk areas in your home, which include most patio doors, storm doors, and any large windows close to the floor. While its strength makes it suitable for all standard windows in urban or suburban homes, its primary role is to prevent serious injury by shattering into small, blunt pieces when broken, making it the default, affordable choice for these essential safety zones.

Laminated Glass: Security and Comfort

Laminated glass is made of two or more panes bonded with a plastic interlayer, keeping shards together if broken.

Laminated Glass Pros

- Holds shards in place, reducing injury risk.

- Stronger against forced entry: If a burglar tries to break it, the glass shatters, but the plastic interlayer holds all the pieces together. This keeps the glass in the frame and forces the intruder to spend significant time and make substantial noise cutting through the tough inner layer, which usually causes them to give up.

- Blocks UV rays: The PVB (polyvinyl butyral) interlayer is extremely effective at blocking nearly 99% of damaging ultraviolet (UV) rays. This prevents sun-fading and deterioration of expensive interior items like hardwood floors, rugs, curtains, and furniture, helping to preserve your home's interior value and appearance.

- Reduces noise from traffic or nearby construction: The flexible plastic interlayer acts as an excellent sound dampener. It absorbs sound vibrations, significantly reducing noise pollution from busy streets, air traffic, trains, or loud neighbours.

- Offers decorative or tinted options.

- If it breaks: Like tempered glass, it is a safety glass because the sharp shards remain glued to the plastic, keeping the pane intact: no sudden, open hole or glass to clean up.

Laminated Glass Cons

- Heavier: The addition of the interlayer and the second pane of glass adds substantial weight. This may require stronger, more robust frames and specialised hardware (like hinges for doors), which can add to the total installation cost.

- Higher upfront cost: Due to the added materials (the plastic interlayer) and the specialised manufacturing process, laminated glass is significantly more expensive than standard or even tempered glass of the same thickness.

- Slightly reduced light transmission: While often negligible, the interlayer is another material layer that can slightly reduce the amount of visible light entering your home compared to a standard single pane. This can be more noticeable if decorative or tinted options are chosen.

Laminated glass is the preferred upgrade when you need protection beyond the basic safety code, making it ideal for residential areas where security and comfort are paramount. It is best used for ground-floor and entrance doors where its resistance to forced entry provides peace of mind, for noise-sensitive rooms like bedrooms and offices facing busy streets where its sound-dampening qualities reduce noise pollution, and for large picture windows where its ability to block nearly all UV rays prevents high-value furniture and floors from sun-fading.

Tempered vs Laminated Glass: Quick Comparison

| Application | Tempered Glass | Laminated Glass |

|---|---|---|

| Standard windows | Cost-effective | Heavier, more expensive |

| Entrance doors | Meets code | Improves security & style |

| Sliding patio doors | Durable | Safety, UV, and noise reduction |

Why Ottawa Homeowners Should Consider Climate and Security

- Climate: Ottawa’s cold winters, heavy snow, and freeze-thaw cycles can affect large glass panels. Laminated glass adds weight—ensure your frame and hardware can support it.

- Security: Rural and suburban homes may benefit from laminated glass to resist break-ins or storm damage.

- Noise: Laminated glass reduces traffic and construction noise.

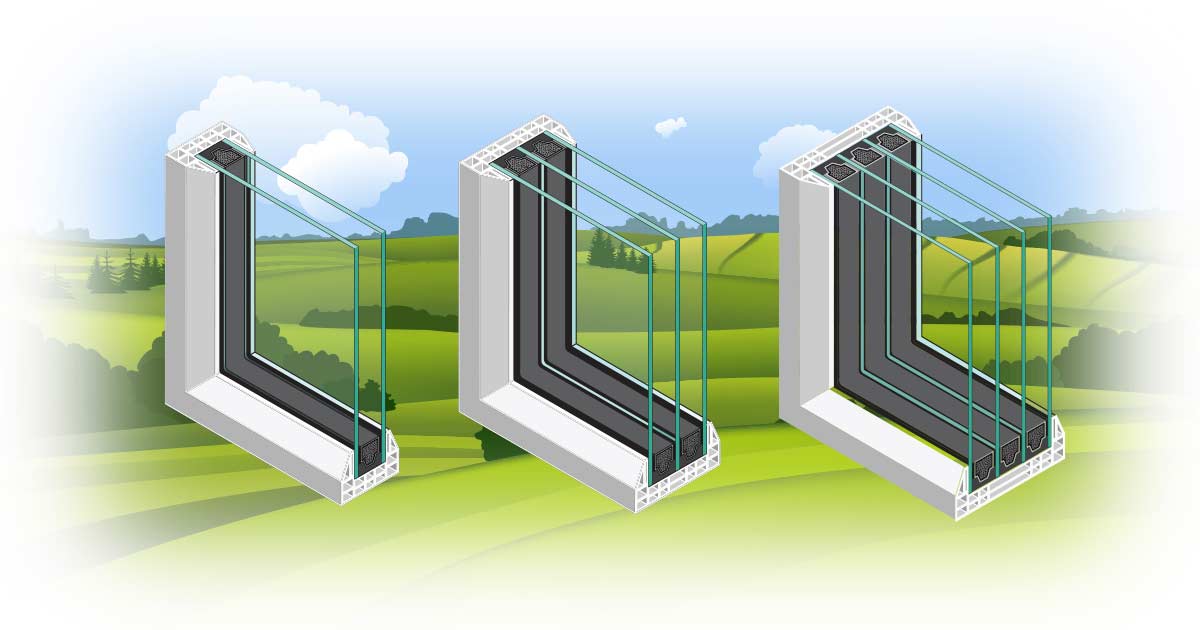

- Energy efficiency: Multi-layer glazing with laminated or hybrid glass helps reduce heating costs.

FAQs: Laminated vs Tempered Glass

- Do I need laminated glass for my sliding patio door in Ottawa?

- Laminated glass is ideal if you want extra security, noise reduction, and UV protection, especially for large doors or exposed locations.

- How much more does laminated glass cost?

- Typically, 10–25% more than tempered glass, but the added safety and energy efficiency may justify the investment.

- Can tempered glass be replaced with laminated glass in existing frames?

- It depends on the frame and hardware. Some older doors or windows may need adjustments to handle laminated glass.

Choosing the Right Glass for Your Ottawa Home

- Safety: Tempered glass is safe for standard applications.

- Security: Laminated glass resists break-ins and storm damage.

- Noise & comfort: Laminated glass reduces outside noise.

- Energy efficiency: Hybrid or multi-layer glazing improves insulation.

Final Thoughts

There’s no one-size-fits-all answer when choosing between laminated glass and tempered glass.

Tempered glass offers strong, safe breakage behaviour at a lower cost, making it ideal for standard windows, patio doors, door glass and other applications where safety and affordability are priorities.

Laminated glass, on the other hand, adds an extra layer of protection, enhancing security, sound reduction, and UV control, which makes it an excellent choice for decorative door glass, large picture windows, sidelites, and areas exposed to potential impact or intrusion.

Related articles

Need help figuring it out?

For high-demand settings, hybrid or multi-layer glazing systems can combine both technologies, providing the strength of tempered glass with the retention and acoustic benefits of laminated glass.

By assessing your specific requirements, whether safety, security, noise reduction, UV blocking, energy efficiency, or aesthetic appeal, you can choose the glazing option best suited to your application and environment.

per window/door opening

for Windows and Doors